Construction for the Hunter’s Point South project started on January 10, 2011. The project was bid out by the New York City School Construction Authority (SCA) as a Lump Sum Bid to SKANSKA, a world leader in construction management. Construction of the new intermediate and high school will take approximately 33 weeks to complete, with an estimated completion date in October 2013. Construction costs for the project are estimated at $61,098,000.

|

|

Structural Systems

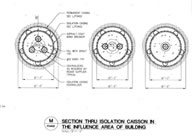

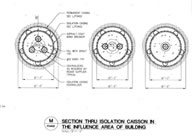

Foundation:

The foundation consists of a 12” 4000psi reinforced slab on grade supported by a system of grade and strap beams, 14” caissons, and steel H-piles. Special isolation caissons were used for locations within 50 feet of two subsurface tunnels used for the Queens-Midtown easement line that run E-W through the site. A geotechnical survey performed by Langan Engineering showed soil type ranges from grey silty sand to clay, with bedrock consisting of Gneiss starting at about 40 feet below grade.

|

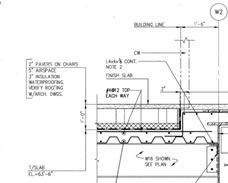

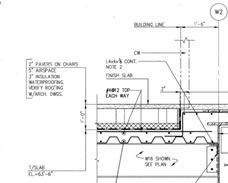

Floor:

The floor system consists typically of 3 ¼” thick 3500psi lightweight concrete on 3” deep composite 18 gage galvanized metal deck (6 ¼” total depth) supported by a steel framing system. Concrete is reinforced with 6x6 W2.0xW2.0 WWF. The floor system above the gymnasium will consist of acoustical metal deck in place of typical deck. The auditorium stadium seating floor will have 16 gage deck in place of typical deck. All cast-in-place concrete slabs are reinforced by #4 reinforcing bars spaced 12” in both directions.

|

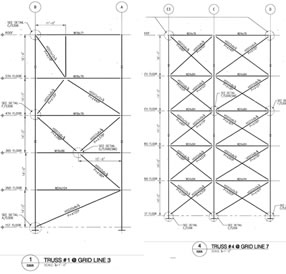

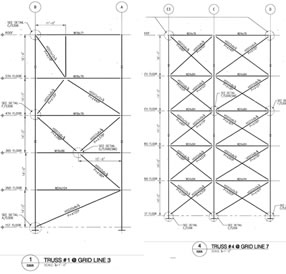

Framing and Lateral System:

The superstructure of Hunter’s Point is typically comprised of W10 steel columns supporting W24 girders and either W14 beams at the building core or W16 beams towards the perimeter of the structure. Sizes and span lengths vary throughout the building. The lateral force resisting system consists of both HSS and wide flange lateral truss bracing, along with steel moment connections at columns around the gymnasium and auditorium spaces. The majority of the lateral bracing is placed in the N-S direction.

|

|

Mechanical Systems

HVAC:

Conditioned air is served to Hunter’s Point South Intermediate School & High School via the six rooftop air handling units. Units 1, 2, and 3 are variable air volume (VAV) systems that service the classrooms, offices, corridors, and non-public spaces. Units 4, 5, and 6 are constant air volume (CAV) systems that serve the gymnasium, cafeteria/kitchen, and auditorium, respectively. All air handling units have variable frequency drives and wrap around heat pipes. Preheat coils in the AHU’s use a 35% propylene glycol – water mixture while the cooling coil utilizes a 30% propylene glycol – water mixture. This heat-transfer fluid has low toxicity and volatility. It poses little harm to humans in case of a leak.

Four gas fired, condensing boilers are used for Hunter’s Point South School’s heating needs. These boilers are located in the mechanical penthouse’s boiler room. Each boiler can produce 1860 MBH worth of 35% propylene glycol – water mixture at 212°F and 160 psig. All heating hot water and secondary pumps are located in the boiler room along with the hot and chilled water expansion tanks. Two 27 ton air cooled water chillers are also located on the roof. A 30% propylene glycol – water mixture is cooled by the R-140a refrigerant which is used for the AHU’s cooling coils.

Cabinet and unit heaters are used to heat the building’s entrances, locker rooms/showers, and stairwells. Split heat pumps are utilized in the telecom rooms on each floor, food storage, and elevator machine room. The outdoor section of each heat pump is located on the roof. Upblast and mushroom fans are located on the roof where they exhaust air from the science lab’s fume hoods and kitchen.

|

Plumbing:

The domestic water supply is fed into the plumbing room on the first floor through a 4” service pipe. Two 180 gpm booster pumps then push the water to the boiler penthouse on the roof, where it is heated by a gas fire and circulated throughout the building by two additional pumps. The boiler room also includes a 504 gallon water tank and 132 gallon expansion tank.

High-pressure gas is also fed into the building to be used for boilers, water heaters, kitchen equipment, and science lab burners. The gas is fed into the building and into the gas room on the first floor by a 4” service pipe. Gas exhaust is vented to the roof.

The building also has three waste lines. There is a 6 inch sewer line and 8 inch and 10 inch storm drain pipes that are fed out from the first floor and into the city’s sewer system.

|

|

Lighting/Electrical Systems

Lighting:

Hunter’s Point South utilizes mainly florescent lighting throughout the building. 32 Watt tubes and compact fluorescents (CFL’s) are used. Fixtures include cans, wall washers, and pendants. The gymnasium space uses 8 tube fluorescent pendent fixtures rather than high intensity discharge lamps (HID) most commonly used in that situation. The auditorium uses incandescent lighting to create the correct color rendering.

This building has both lighting control and emergency lighting. The main lighting control is separated into zones that include like room types (i.e. classrooms). Singular room lighting control is done with timing and occupancy sensors. Emergency lighting is on a different control zone than the rest of the building and includes stair lighting, exit signs, and other necessary lighting.

|

Electrical:

The entire building uses a 120/208 Volt electrical system that supports 6000 Amps. The system is a radial system that has a main service input source that feeds into 2 main switchboards in the electrical room on the first floor, and then branches of radially to supply the building with electricity. Each floor has two connecting electrical rooms that carry the main conduit vertically through the building. One room is meant to house all normal power systems, while the other is strictly for emergency power. Emergency power is generated by an on-sight generator and powers all emergency lighting, elevators, fire system, and other equipment necessary for operation.

|

|

Miscellaneous Systems

Fire Protection:

The fire protection system consists of a wet standpipe and sprinkler system. Sprinkler heads are a mix of upright and concealed heads. There is a 1000 gpm vertical split case pump that initially pressures the sprinkler lines and several centrifugal jockey pumps help sustain that pressure throughout the building. Two 8” pipes are designated as the water feed pipes into the building and are brought into the plumbing room for circulation throughout the building.

|

Transportation:

Hunter’s Point South has 2 elevators at the center of the building that service all 5 floors. There are two main staircases at both the north and south entrances. Another staircase is located on the north side of the east wing of the building. Means of egress can be found at all four ends of the two main hallways, with an additional exit on the south side of the east wing.

|

|